July 25, 2022

The ancient craft of spinning – twisting together fibers of wool, cotton, flax, or silk to create thread or yarn – has never been lost. Once a necessity for creating textiles for clothing and furnishings, spinning is now a craft pursued by artisans and hobbyists as an expression of personal creativity. A new exhibit at the Colonel Paul Wentworth House, Wheels of Industry: New England Spinning Wheels, features several examples of these important tools of domestic industry. The exhibit is on view on Saturdays from 1 to 4 pm through October 8, and at other times by appointment.

Drawn primarily from the collection of Peter and Nancy Cook of Tare Shirt Farm in Berwick, Maine, Wheels of Industry features a variety of early and unusual spinning wheels, including great wheels, treadle wheels, double flyers, a chair wheel, and a castle wheel. While some of the wheels were made by local artisans, the majority were produced throughout New England and, in one case, Quebec.

In conjunction with Wheels of Industry, the Wentworth House is also hosting Spinning Sundays on the last Sunday of each month through September of our 2022 season. Visitors are invited to drop in and learn to spin from 11 am to 1 pm (free; all materials provided and no registration required), or bring their own wheel or other fiber arts project to a Spin-In from 1 to 4 pm. As an added bonus, on July 31 at 1 pm, textile expert Peter Cook will demonstrate flax processing, followed by a guided tour of the exhibit.

The evolution of the spinning wheel

The earliest spinning technology generally involved the use of a distaff to hold the fiber and a hand spindle to twist the fiber. The use of a spinning wheel to put a twist into the fiber evolved from the hand spindle, probably around 1000 AD in Asia, with the technology reaching Europe during the Middle Ages.

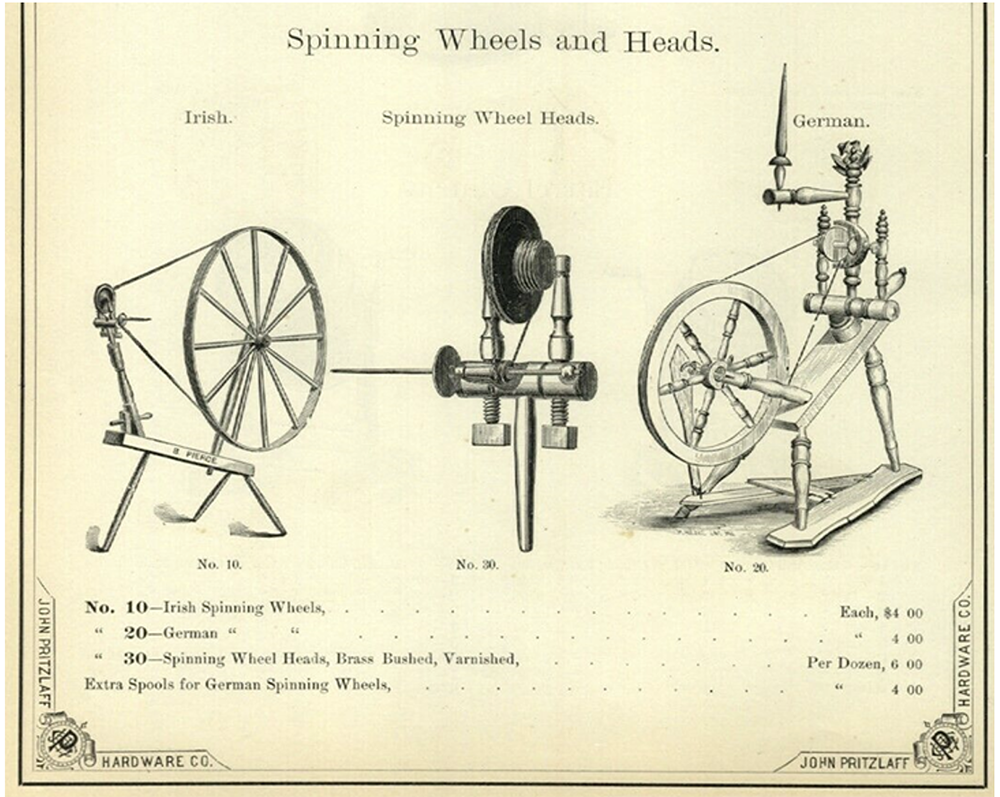

The function of a spinning wheel is to facilitate the draft of long continuous fibers of wool or flax into yarn or thread. On a wool or “great” wheel, the twist of yarn is achieved by the fiber falling off the iron point as the wheel is turned by hand while the spinner walks back and forth. Treadle wheels (sometimes called flax wheels, linen wheels, or “Saxony” wheels) use foot power to spin and wind the spun thread on spools through the manipulation of fibers drawn from the large distaff.

The craft of spinning is common to many cultures worldwide, and the many ethnic groups that settled in America continued to practice hand spinning using methods and wheels which reflected their regional heritage. This in part accounts for the variety of spinning wheels. Technological innovations also play a large role in the wide variety of wheels. A great wheel clearly takes up a lot of room, while the smaller treadle wheel requires less space, frees up the spinner’s hands, and is easier to transport from place to place. Spinning wheels with a vertical wheel arrangement (such as the castle wheel) also save space. Other innovations such as accelerator wheels and double flyers improved the speed and efficiency of the spinning process.

(Left) Spinning on a treadle wheel (Right) Spinning with a great wheel

Spinning in Old New England

In the United States, the spinning wheel has long been recognized as a symbol of colonial domesticity. Many (but by no means all) early New England households included a spinning wheel in their furnishings. In the 18th and into the 19th century, homespun textiles were generally used for work clothing, bed and table linens, and children’s garments. During periods of conflict with Great Britain, making and wearing homespun textiles (as opposed to buying imported cloth) was encouraged as an act of patriotism. But generally speaking, manufactured textiles were more desirable, especially for clothing, and as industrialization made these textiles cheaper and more widely available, spinning wheels fell into disuse, especially in urban areas.

An examination of a small sample of household inventories from old Somersworth illustrates both a pattern of ownership of both types of wheels (wool wheels and the more valuable flax or linen wheels) as well as the decline in spinning as a domestic industry in the 19th century.

The 1748 probate inventory for Colonel Paul Wentworth’s estate notes “1 Linnen Wheel” in the small southwest chamber of the Wentworth House, valued at 3 pounds, 10 shillings, and two woolen wheels elsewhere in the house, valued together at 50 shillings (equivalent to 2 ½ pounds). Additionally, Colonel Wentworth’s inventory lists a flax comb, 18 pounds of combed flax, 20 pounds of cotton wool, 44 pounds of sheep’s wool, “a quantity of mean flax in ye warehouse,” 23 “old Sheep,” and 14 lambs. Clearly Colonel Wentworth’s farm was producing both wool and flax, and someone in the household was spinning, whether it was his late wife, his daughter-in-law, his niece Mary or the enslaved woman Dinah.

In the mid-1700s, Colonel Thomas Wallingford, another resident of old Somersworth, was one of the richest men in pre-Revolutionary New Hampshire, with extensive property holdings throughout the colony. The 1771 inventory of the contents of his home in the Sligo area of the town lists four spinning wheels: two wheels in one of the bed chambers (“2 wheels, one wooling, ye other Linnen”) together valued at 16 shillings, and another two in the kitchen: one wool wheel, valued at 5 shillings, and a linen wheel valued at 14 shillings. Elsewhere in the house, the inventory notes some wool and linen yarn and a flax comb. Rather surprisingly there are no sheep listed among Colonel Wallingford’s livestock. Perhaps the spinners in his household obtained their raw materials from neighboring farms.

By the mid-1780s, the Wentworth House was owned by Colonel Paul Wentworth’s great nephew Andrew. The inventory taken after Andrew died in 1813 lists “one large wheel & one foot wheel” (together valued at only $1.25), eleven sheep, and nine lambs. Presumably the property was still producing wool but it is not listed in the inventory nor is there any mention of the tools needed to process flax.

By the mid-1780s, the Wentworth House was owned by Colonel Paul Wentworth’s great nephew Andrew. The inventory taken after Andrew died in 1813 lists “one large wheel & one foot wheel” (together valued at only $1.25), eleven sheep, and nine lambs. Presumably the property was still producing wool but it is not listed in the inventory nor is there any mention of the tools needed to process flax.

By the time Andrew’s son and heir Major John B. Wentworth passed away in 1869, neither spinning wheels, nor sheep, nor any other textile-related tools were listed in his inventory at all. The many mills operating throughout New England were producing textiles for clothing and furnishings, and while spinning wheels might have continued in use in rural areas to process wool or flax raised by the family, many spinning wheels were relegated to attics and barns.

The Colonial Revival era of the late 19th and early 20th centuries romanticized much about the colonial era, including the craft of spinning, and no “colonial” house interior was complete without a spinning wheel. A spinning wheel came to be more valued as relic of the past or as a decorative arts example of furniture than as a useful and necessary tool. Fortunately, there has been a revival of interest in spinning, and dedicated artisans are keeping the craft of spinning alive along with an appreciation for these important domestic tools of domestic industry.